FUBAR

Can Better Project Management Save the World?

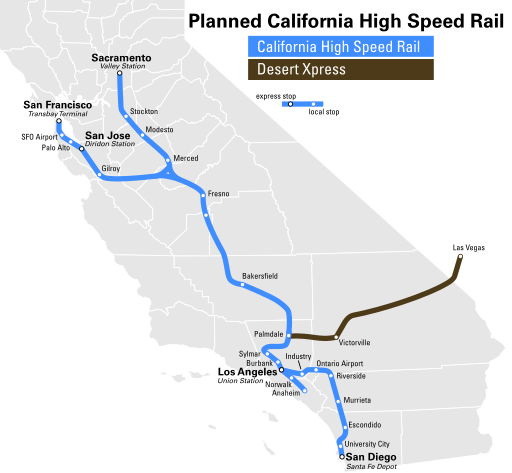

Boondoggle projects seem to be the rule rather than the exception. Many people might guess that, having had personal experience with the run-of-the-mill incompetence that seems to affect all bureaucracies, corporate or governmental. In 2008 Californians pledged to spend $9 billion on a high-speed rail between Los Angelos and San Francisco. Fifteen years later, no rail has been laid and cost estimates have reached the neighborhood of $100 billion. It is now projected that only in the 2030’s will a, mostly useless, line between Bakersfield and Merced be operational.

Cal HSR: Will it ever get built? Credit: CountZ

Yet there are rare exemplars. Construction of the Empire State Building not only came in underbudget but on time: A little over 13 months to erect 102 floors. Or, to take a more modern example, Pixar studios reliably churns out hit after hit, seeming to have figured out the secret sauce for putting together a successful movie before powering up their giant computer rendering farms. Why do some megaprojects flounder, while, at other times, people seem capable of rising to the challenge of their complexities?

In How Big Things Get Done, Danish academic Bent Flyvbjerg and journalist Dan Gardner provide the recipe for successfully managing large projects. While some suggestions, like more detailed planning, are fairly mundane, other recommendations force us to think more deeply about how to organize ourselves for intelligence, and about which technologies are compatible with doing so. Flyvbjerg and Gardner’s book is a great guidebook for better project management, but its scope is limited. Readers looking for insight on how to tackle humanity’s biggest projects, like addressing climate change or averting an AI-driven catastrophe, will feel underwhelmed.

Planning for Learning

Bad project management can be summed up in one word: overconfidence. As Flyvbjerg and Gardner illustrate through several cases, failed projects happen because the people involved don’t appreciate the complexity of their undertaking. From a straightforward kitchen renovation that spiraled to $800 thousand in cost to China’s stumbling efforts to build a high-speed rail line into Hong Kong, the lesson is for managers to recognize the need for learning and to maximize their chances of doing so.

One of the biggest stumbling points is the urge to get started quickly. As Flyvbjerg and Gardner point out, there are often political pressures to deliver a project fast. The Sydney Opera House is one example, where workers broke ground before anyone really knew how to build Jørn Utzon radical design, which at the time wasn’t much more than a rough sketch. But New South Wales premier Joe Cahill decreed that construction would begin in February of 1959. Starting without adequate planning meant that early work had to be demolished later, when it proved inadequate. This failing, among others, contributed to a cost overrun of 1,400 percent.

Sydney Opera House: A stunning failure. Credit: Bernard Spragg. CC0, via Wikimedia Commons

Flyvbjerg and Gardner compare these failures to the planning process utilized by Frank Gehry and at Pixar. Successful creation means iteration. This is because the most reliable learning comes from experience. Gehry would model his designs over and over. And when computers became available, he simulated them. Pixar pitches are constructively criticized in multiple stages, from plot summary to full scrips and storyboards. They actually shoot their films twice: once as a set of thousands of hand drawn sketches and again in the rendering farm. Recognizing that it is far cheaper to fix mistakes or polish the plot earlier rather than later, Pixar wait until they are completely satisfied with the product before animating it.

Other recommendations from Flyvbjerg and Gardner build off the central recognition of the primacy of experience. Megaprojects should be done by people with expertise in that very same kind of undertaking. The company that built the Empire State Building constructed a nearly identical, albeit shorter, version just a few years before in North Carolina.

Projects should be designed to be modular as well. Constructing the Empire State Building wasn’t exactly like building a 102-story building as much as building 102 one-story buildings on top of one another. The design helped workers work out kinks and hone their process as they went on, something that wouldn’t have happened if each floor presented totally unique challenges. As Flyvbjerg and Gardner put, every piece of a megaproject should be a “Lego,” a basic (and smaller) building block that gets repeated. Consider how the Madrid Metro expanded by 76 stations in the mid-90s—and compare that to decadal efforts to add a few stations in Los Angeles or New York. Planners used off the shelf tunnel boring machines and standardized station designs, treating tunnel segments like stacking up Legos.

A final recommendation is to work to ensure that those involved are bought into the project and to work to quickly resolve costly conflicts. Flyvbjerg and Gardner give the example of the Heathrow Airport expansion. Recognizing that success depended on avoiding shut downs, managers ensured that workers were well resourced. If they needed new gloves or safety glasses, new ones were promptly provided. They were empowered too. Skilled workers developed their own quality benchmarks to apply to their workmanship. Furthermore, a potential conflict between subcontractors was averting by rewriting the contract so that the two benefitted the most by working together, rather than by pointing fingers at one another.

These lessons are well researched and compelling. But it was a shame that How Big Things Get Done makes no mention of scholars who demonstrated very similar things decades ago. David Collingridge’s book, The Management of Scale, appeared in 1992. And it articulated many of the same points: keep unit sizes small (i.e., aim for modularity) and aim to avoid high capital intensity, heavy infrastructural investments, and designs requiring long lead times.

Collingridge also highlighted the need for productive disagreement. It is a concept that is more expansive than Flyvbjerg and Gardner’s examples of Gehry’s indefatigable dissatisfaction with early models and of Pixar’s culture of constructive criticism. Collingridge warned against “yes men” culture or the overdominance of projects by singular groups or personalities, which prevent error from going recognized or discussed openly.

Similarly, Flyvbjerg and Gardner describe the importance of collaborative teams, it sounds a lot like what used to be called “high-reliability organizations.” Research in this area uncovered how to set up workplaces to align everyone’s incentives to overarching goals like assuring safety while maintaining high levels of performance. The social organization on aircraft carriers or in nuclear reactors are just a few classic examples. Flyvbjerg’s work on megaprojects seems to complement this earlier research. But it is less clear how exactly he goes beyond it.

Can All Big Things Get Done?

Flyvbjerg and Gardner provide a handy table that ranks different types of projects in terms of their likelihood to go belly up. The worst, apart from hosting the Olympics, is nuclear energy and nuclear storage. Not only are these projects delayed by popular opposition and some of the most stringent regulations of any industry, the technology itself is massive complex, and nothing about it is modular or mass produced. Erecting nuclear plants is more like building a Ferrari than assembling a Ford. The industry seems to show the opposite of learning, with the new nuclear plants coming online at Vogtle arriving years behind schedule and billions overbudget. The question is, can nuclear get done at all?

The nuclear industry is at least trying to learn from the past. Small modular reactors (SMRs) are being touted as a pathway to move nuclear reactor construction to the assembly line. But even the effort to modularize is hampered by outside factors. Nuclear Regulatory Commission regulations demand that these more inherently safe reactor designs address the same kinds of “what if’s?” as the more catastrophe prone plants of the 60’s and 70’s. And the United States now has no domestic supply of uranium fuel. Potential buyers are understandably apprehensive. The industry is stuck in a catch-22, in which utility companies won’t commit funding for an unproven technology, but the technology can’t prove itself without financing and places to install it.

Vogtle Nuclear Power Plant: New reactors…eventually. Credit: Charles C Watson Jr, CC BY-SA 3.0

Yet, even SMRs are not really small. Holtec’s will be 160 MW, while NuScale is chaining together 50 MW reactors in gigawatt scale plants. The fact that design and deployment schedules are already lagging demonstrates that SMRs as still big enough to be awesomely complex. NuScale estimates a three year build time for their reactors. And the modularity of the technology is limited by the reality that, as early nuclear engineers found out, hooking up an atomic reactor to a power plant is still more complicated and capital intensive than installing a coal-fired boiler.

I am not sure whether the economics of starting truly small are congenial, but it is worth exploring. Micro reactors could power military bases, Department of Energy laboratories, or hospital complexes, places that are already secure and need reliable energy. Aiming lower would given SMR firms a chance to really work the kinks out of the designs and build confidence in the technology. But the price premium might be too high for that approach, absent governmental subsidy.

In any case, it remains an open question whether nuclear energy per se cannot “get done.” Even the renewable energy technologies lauded in the book haven’t always been modular or gradually implemented. Flyvbjerg and Gardner actually leave out the most interesting parts when they write about Danish wind turbine history, events that shows that the problem may more often lie with creators’ mindset than technologies themselves.

Their book has less to tell us about how to better resolve the thornier and more urgent issues that humanity now faces.

The Danes (similar to the Americans and Germans) had initially taken a decidedly non-modular approach to wind turbines. All three committed millions to unsuccessful federal R&D projects that tried to go too big, too fast. In the USA, NASA engineers built gargantuan turbines with the most sophisticated aerodynamics and materials of the era, only for the machines to fall apart under real-life conditions, sometimes in the matter of hours. Even though NASA pioneered technologies now in use today, both they and their commercial partners left the industry by the early 90s.

The current Danish industry, even though it now builds megawatt sized turbines in fields of 100’s of machines, has its roots in small-scale agricultural implement companies that tinkered with a small-scale traditional turbine design. Government subsidy and test stations provided some impetus for continual improvement, but the gradual evolution to reliable turbines was more decentralized than centrally steered. Turbine builders even organized their own journal to share successes and problems.

Flyvbjerg and Gardner might have left this part of the story out because it runs orthogonally to their thesis that it is better project management that ensures that big things get done. Though, to be fair, they do mention “Danes tinkering in garages.” Perhaps 1970s NASA engineers would have been successful had Flyvbjerg been around at the time to guide them. But it could also be that a lot of vital learning about technologies happens between firms rather than within them. Gains in nuclear energy and commercial aviation safety, for instance, was spurred by companies banding together to share information about mistakes and mishaps, albeit also in response to regulatory pressure.

Zeroing in on what happens within a single organization keeps their book focused, and makes it an attractive buy for itinerant professionals browsing airport bookstores for reading material. But that focus means that their book has less to tell us about how to better resolve the thornier and more urgent issues that humanity now faces.

Getting the Biggest Things Done

The gravity of the world’s problems is not lost on Flyvbjerg and Gardner. As they argue, “to win the fight against climate change, we must build at a scale and speed that put to shame the long, sorry record of the giant projects of the past.” No doubt it would help if managers of renewable energy, green technology, and infrastructural projects learned from How Big Things Get Done. But the barriers are far larger than just bad project management.

Take one area where progress has been stubbornly paltry: detoxification. Despite no shortage of knowledge of the harms of the chemicals saturating the products we use every day and big governmental regulatory programs to combat them, toxics proliferate in consumer products and in the environment. Outside a few policies that tinker on the margins, like plastic straw and bag bans, there doesn’t seem to be a clear pathway to far fewer plastics and synthetic chemicals in the environment (and thereby less microplastic and toxins in our bodies).

We must do nothing short of more effectively harnessing the awesome intelligence distributed throughout society to solve our most pressing problems.

While these kinds of issues take us away from the relatively well-structured projects that Flyvbjerg and Gardner focus on, they are arguably the most important, the biggest megaprojects that humans are failing to manage. They involve an array of firms, governments, and NGOs with diverse interests and goals, which somehow need to work together well enough to face up to awesome challenges. While How Big Things Get Done doesn’t tackle these ultramegaprojects, that doesn’t mean that Flyvbjerg’s research wouldn’t have anything relevant to say about them. Scaled up beyond project management, Flyvbjerg and Gardner’s lessons could help us design a better system for detoxifying Americans’ lives.

The Toxic Substance Control Act (TSCA) requires that the Environmental Protection Agency designate certain chemicals as “high priority”, evaluate their risks, and them impose restrictions to eliminate “unreasonable risk.” The legislation has been a failure, with tens of thousands of chemicals grandfathered in and very few chemicals actually being evaluated. The 2016 Lautenberg Act seems to have achieved some improvements, but the Environmental Protection Agency (EPA) has only completed a risk evaluation for an additional eight substances since then, rolling out final rulings on a handful of persistent toxics since 2020.[i]

Because it tries to restrict chemicals long after they have become widespread, the TSCA is high stakes politics. Chemical companies have understandably fought tooth and nail against it. Due to the high costs of error, if the EPA unduly bans a useful and profitable chemical, the industry prefers that no trials happen at all.

Flyvbjerg and Gardner tout the power of good planning. And good planning means being set up to learn through iteration, through trial and error. The trouble with US toxic chemical policy is that, while it is set up to try to learn about the hazards posed by manmade substances, it wasn’t designed to learn how to gradually become more effective in removing those chemicals from our lives.

Rather than seek authoritative statements on the “unreasonable risk” of a chemical, the EPA would be better off prioritizing low-hanging fruit. What are the fairly low-stakes toxic chemicals that could help the agency gain experience in eliminating toxins from people’s lives and the environment? Forty percent of decaf coffees contain trace amounts of methylene chloride. That might be perfectly harmless. But when companies can just as well decaffeinate with CO2 or plain old water, why should we keep around an outdated process that uses the main ingredient in paint stripper?

Working through the political conflicts involved when reducing or eliminating toxic chemical processes should be the agency’s Lego, not trying to develop authoritative risk assessments. In this regard, the EPA could learn a great deal from Massachusetts’s Toxics Use Reduction Institute (TURI), which has achieved dramatic declines in toxic releases within the state. Shunning the adversarial model of the TSCA, Massachusetts’s agency collaborates directly with businesses to discover how the reduce toxic chemical use without harming the end product.

The result is a productive combining of experience, industry and state scientists working together to realize more benign chemical processes. Imagine if we had something with the power and resources of the American federal government to iteratively and collaboratively develop alternatives to plastic products that perform just as well, if not better, while still being similarly economical?

While it was probably wise for Flyvbjerg and Gardner to have kept How Big Things Get Done focused on good organizational planning, it is a shame that they cast their net so narrowly. They underappreciate how sorely needed intelligent trial and error strategies are nearly everywhere and at scales far higher than project management. We must do nothing short of more effectively harnessing the awesome intelligence distributed throughout society to solve our most pressing problems. Only then can we get the biggest things done.

[i] The EPA may have done better than this, but their website is so disorganized that it is challenging to find simple information answering the question: “How successful has the EPA been had regulating toxic chemicals?”